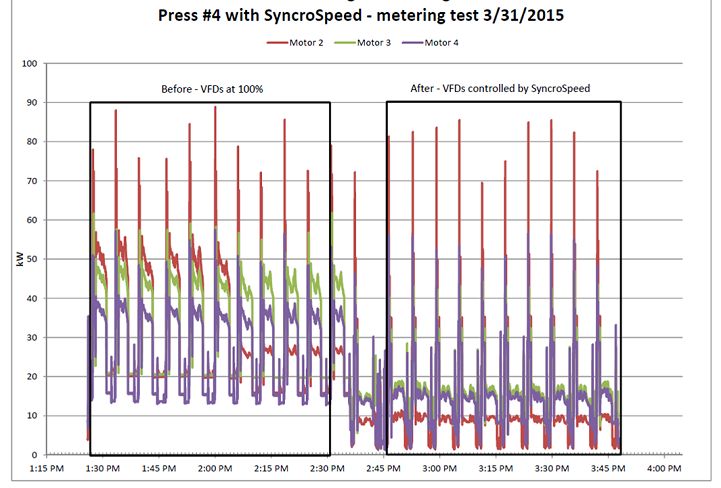

A recent SyncroSpeed installation delivered savings beyond the expectation of all. Prior measurement and analysis forecast a very positive result, but more was achieved with this 3-motor SyncroSpeed system retrofit to an HPM 1100t machine. SyncroSpeed supports an advanced independent control strategy for each motor to maximise the reductions.

The SyncroSpeed performance was scrutinised by Efficiency Vermont, who were pleased to officially report a reduction in motor load of 48.8kW, representing a 53% saving. LIZ GAMACHE, Director of Efficiency Vermont says …” we advance sustainable energy solutions for all Vermonters. I’d like to invite you to work with us and see how we can help.”

The CCS SyncroSpeed installation crew were under threat from the Plant Manager for a free dinner if results were as good as 50%. Looks like they have something extra to look forward to in Vermont next time!

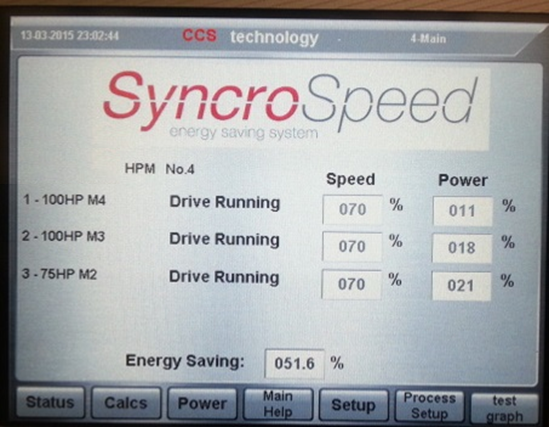

Status and performance information from the SyncroSpeed HMI. SyncroSpeed comes with a 5.7” colour touchscreen, rich in information.

Efficiency Vermont verifies SyncroSpeed savings delivery. The SyncroSpeed system seeks and delivers savings throughout the entire cycle of the IMM. Shot after shot, cycle after cycle.

Smile, it’s a great result! Leading the installation process, Tiziano is very pleased with the results, and he shows it!